Is L-ergothioneine powder natural or synthetic?

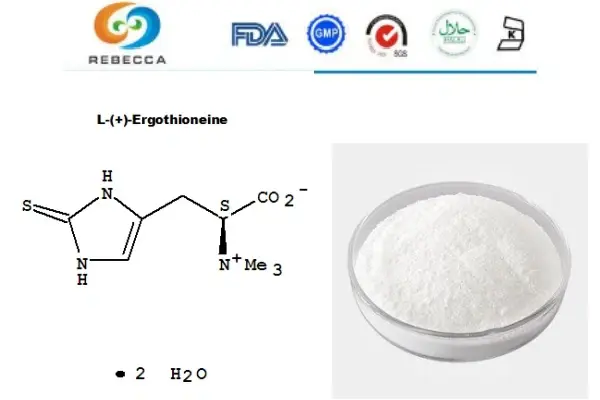

L-ergothioneine powder, a powerful antioxidant amino acid, has gained significant attention in recent years for its potential health benefits. As interest in this compound grows, many people wonder whether L-ergothioneine powder is derived from natural sources or if it's synthetically produced. In this comprehensive guide, we'll explore its origins, its natural sources, extraction methods, and synthetic production processes.

What are the sources of L-ergothioneine powder?

L-ergothioneine is found naturally in various organisms, primarily in certain fungi and some bacteria. The most abundant natural sources of L-ergothioneine include:

- Mushrooms: Edible mushrooms are the richest dietary source of L-ergothioneine. Species such as oyster mushrooms, shiitake, and king oyster mushrooms contain particularly high levels of this compound.

- Fungi: Besides edible mushrooms, other fungi like certain molds and yeasts also produce L-ergothioneine.

- Bacteria: Some bacterial species, particularly those belonging to the Actinobacteria phylum, can synthesize L-ergothioneine.

- Plants: While not as abundant as in fungi, trace amounts of L-ergothioneine can be found in some plants, especially those growing in soils rich in ergothioneine-producing microorganisms.

- Animal products: Small quantities of L-ergothioneine can be detected in animal products, likely due to the animals consuming ergothioneine-containing plants or fungi.

It's worth noting that humans and other animals cannot produce L-ergothioneine themselves, making it an essential nutrient that must be obtained through diet or supplementation.

How is natural L-ergothioneine powder extracted?

The extraction of natural L-ergothioneine powder involves several steps and can be accomplished through various methods. Here's an overview of the typical extraction process:

- Source selection: Mushrooms or other fungi rich in L-ergothioneine are chosen as the starting material. The selection is based on the ergothioneine content and the ease of cultivation or harvesting.

- Preparation: The fungal material is cleaned, dried, and often ground into a fine powder to increase the surface area for extraction.

- Extraction: Various extraction techniques can be employed, including:

- Solvent extraction: Using water, ethanol, or other solvents to dissolve and extract L-ergothioneine from the fungal material.

- Supercritical fluid extraction: Utilizing supercritical carbon dioxide as a solvent to extract L-ergothioneine under high pressure and temperature conditions.

- Enzymatic extraction: Employing specific enzymes to break down cell walls and release L-ergothioneine from the fungal tissue.

- Purification: The extracted solution undergoes several purification steps, which may include:

- Filtration to remove solid particles

- Chromatography techniques to separate L-ergothioneine from other compounds

- Crystallization to obtain pure L-ergothioneine crystals

- Drying: The purified L-ergothioneine is dried using methods like freeze-drying or spray-drying to produce a stable powder form.

- Quality control: The final product undergoes rigorous testing to ensure purity, potency, and safety before being packaged as L-ergothioneine powder.

The extraction of natural L-ergothioneine is a complex process that requires specialized equipment and expertise. As a result, the production of high-purity natural L-ergothioneine powder can be relatively expensive compared to synthetic methods.

How is synthetic L-ergothioneine powder manufactured?

Synthetic L-ergothioneine powder is produced through chemical synthesis in laboratory settings. This approach offers several advantages, including scalability, consistency, and potentially lower production costs. The synthetic production of L-ergothioneine typically involves the following steps:

- Precursor synthesis: The process begins with the synthesis of key precursor molecules, often starting from readily available amino acids or other organic compounds.

- Thiol formation: A critical step in the synthesis involves the formation of the characteristic thiol group present in L-ergothioneine.

- Ring closure: The imidazole ring structure of L-ergothioneine is formed through a series of chemical reactions.

- Stereochemistry control: Careful control of reaction conditions ensures the correct stereochemistry of the final product, as L-ergothioneine is a specific isomer.

- Purification: The synthetic L-ergothioneine undergoes multiple purification steps, including crystallization, chromatography, and recrystallization to achieve high purity.

- Drying and milling: The purified product is dried and milled to produce a fine powder with consistent particle size.

- Quality assurance: Rigorous testing is performed to verify the identity, purity, and safety of the synthetic L-ergothioneine powder.

Several synthetic routes have been developed for L-ergothioneine production, with ongoing research aimed at improving yield, reducing costs, and enhancing sustainability. Some of the most common synthetic approaches include:

- Modification of histidine derivatives

- Total synthesis from simple starting materials

- Biosynthetic pathway engineering in microorganisms

It's important to note that synthetic L-ergothioneine powder is chemically identical to the naturally occurring compound when produced correctly. However, some consumers may prefer naturally sourced supplements, while others may opt for synthetic versions due to potential cost advantages or consistent supply.

Both natural and synthetic L-ergothioneine powders have their place in the market, catering to different consumer preferences and applications. The choice between natural and synthetic sources often depends on factors such as cost, scalability, and specific product requirements.

As research into the potential health benefits of L-ergothioneine continues to grow, we can expect to see further advancements in both natural extraction methods and synthetic production techniques. This progress will likely lead to more efficient and cost-effective ways of producing high-quality L-ergothioneine powder, making it more accessible for use in various industries, including nutraceuticals, cosmetics, and functional foods.

If you're interested in learning more about L-ergothioneine powder or have specific questions about its production and applications, don't hesitate to reach out to our team of experts at information@sxrebecca.com. We're here to provide you with the most up-to-date information and guidance on this fascinating compound.

References:

- Halliwell, B., Cheah, I. K., & Tang, R. M. Y. (2018). Ergothioneine – a diet-derived antioxidant with therapeutic potential. FEBS Letters, 592(20), 3357-3366.

- Cheah, I. K., & Halliwell, B. (2012). Ergothioneine; antioxidant potential, physiological function and role in disease. Biochimica et Biophysica Acta (BBA) - Molecular Basis of Disease, 1822(5), 784-793.

- Alamgir, K. M., Masuda, S., Fujitani, Y., Fukuda, F., & Tani, A. (2015). Production of ergothioneine by Methylobacterium species. Frontiers in Microbiology, 6, 1185.

- Grundemann, D. (2012). The ergothioneine transporter controls and indicates ergothioneine activity - A review. Preventive Medicine, 54, S71-S74.

- Cumming, B. M., Chinta, K. C., Reddy, V. P., & Steyn, A. J. C. (2018). Role of ergothioneine in microbial physiology and pathogenesis. Antioxidants & Redox Signaling, 28(6), 431-444.