Ectoine Biosynthesis Pathway

ectoine, a cyclic amino acid derivative, has gained significant attention in recent years due to its remarkable properties as a compatible solute and its wide-ranging applications in biotechnology, cosmetics, and pharmaceuticals. its biosynthesis occurs in halophilic and halotolerant microorganisms as a response to osmotic stress. Understanding the ectoine biosynthesis pathway is crucial for optimizing its production through fermentation technology.

The biosynthesis pathway involves a series of enzymatic reactions that convert L-aspartate-β-semialdehyde into ectoin. This process is typically carried out by three key enzymes: L-2,4-diaminobutyric acid transaminase (EctB), L-2,4-diaminobutyric acid acetyltransferase (EctA), and ectoine synthase (EctC). These enzymes are encoded by the ectABC gene cluster, which is found in many ectoine-producing microorganisms.

Fermentation Technology Process Production

1. Strain selection: Choosing an appropriate microorganism capable of efficiently producing ectoin is crucial. Common producers include Halomonas elongata, Marinococcus halophilus, and Chromohalobacter salexigens.

2. Media preparation: A carefully formulated growth medium is essential for optimal production. The medium usually contains a carbon source (e.g., glucose), nitrogen source (e.g., ammonium sulfate), and various salts to create the necessary osmotic stress conditions.

3. Fermentation conditions: The fermentation process is typically carried out in bioreactors under controlled conditions. Key parameters include temperature (usually around 30-37°C), pH (7.0-8.0), dissolved oxygen levels, and salinity (often 3-10% NaCl).

4. Induction of ectoine biosynthesis: Osmotic stress is induced by gradually increasing the salt concentration in the medium, triggering the microorganism's natural response to produce ectoin as a protectant.

5. Harvesting and extraction: Once the fermentation process is complete, the cells are harvested, and ectoin is extracted using various methods such as cell disruption followed by chromatographic purification.

6. Purification: The extracted ectoin undergoes further purification steps to achieve high purity levels, often exceeding 99%.

The fermentation technology process has been continuously improved over the years, with researchers focusing on optimizing strain performance, media composition, and process parameters to enhance yield and productivity. For instance, recent studies have explored the use of fed-batch and continuous fermentation strategies to increase ectoin powder titers and streamline the production process.

Other Methods For The Production Of Ectoine

While fermentation technology is the most widely used method for ectoine production, researchers have explored alternative approaches to synthesize this valuable compound. These methods aim to overcome some of the limitations associated with microbial fermentation, such as long production times and complex downstream processing. Here are some alternative methods for production:

1. Chemical synthesis: Synthetic organic chemistry approaches have been developed to produce ectoin through multi-step reactions. One such method involves the cyclization of N-acetyl-L-2,4-diaminobutyric acid. While this approach allows for its production without the need for microbial cultivation, it often results in lower yields and higher production costs compared to fermentation.

2. Enzymatic synthesis: This method utilizes isolated enzymes from the ectoine biosynthesis pathway to convert precursor molecules into ectoine in vitro. Researchers have successfully employed recombinant EctA, EctB, and EctC enzymes to produce ectoin from L-aspartate-β-semialdehyde. This approach offers the advantage of a more controlled reaction environment but may face challenges in terms of enzyme stability and cofactor regeneration.

3. Metabolic engineering: Advanced genetic engineering techniques have been used to enhance production in both native and heterologous hosts. This involves modifying the expression of ectoin biosynthesis genes, optimizing metabolic flux towards ectoine precursors, and engineering regulatory mechanisms to increase overall productivity.

4. Cell-free protein synthesis: This emerging technology uses cell extracts containing the necessary enzymes and precursors in a cell-free environment. While still in its early stages, this method shows promise for rapid and efficient production without the constraints of cellular growth.

5. Synthetic biology approaches: Researchers are exploring the possibility of designing synthetic pathways for production in non-native hosts, such as Escherichia coli or Saccharomyces cerevisiae. This involves introducing the ectoine biosynthesis genes and optimizing their expression in these well-characterized organisms.

Which Method Is Better?

Determining the best method for ectoine production depends on various factors, including scalability, cost-effectiveness, product purity, and environmental considerations. Each approach has its own set of advantages and limitations, and the choice often depends on the specific requirements of the production process and the intended application.

Fermentation technology remains the most widely used and commercially viable method for large-scale ectoin production. Its advantages include:

1. Natural production: Fermentation utilizes the natural biosynthetic capabilities of microorganisms, resulting in a product that is considered "natural" and may be preferred in certain applications, such as cosmetics and nutraceuticals.

2. Scalability: Fermentation processes can be scaled up relatively easily, allowing for industrial-scale production.

3. Cost-effectiveness: Once optimized, fermentation can be a cost-effective method for producing large quantities, especially when using inexpensive substrates and robust production strains.

4. Established technology: Years of research and development have resulted in well-optimized fermentation processes, making it a reliable choice for commercial production.

However, alternative methods like chemical synthesis and enzymatic approaches offer certain advantages in specific scenarios:

1. Purity: Chemical synthesis can potentially yield very high-purity ectoin powder without the need for extensive downstream processing.

2. Speed: Enzymatic and cell-free methods may offer faster production times compared to microbial fermentation, which requires cell growth and adaptation to osmotic stress.

3. Flexibility: Metabolic engineering and synthetic biology approaches allow for the production and its derivatives in well-characterized hosts, potentially simplifying the overall process.

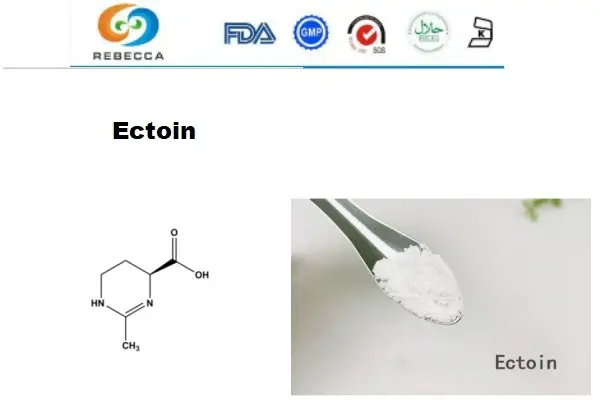

Rebecca Ectoine

Rebecca Ectoine refers to a high-quality ectoin powder developed and manufactured by Rebecca, a company specializing in fermentation technology. This product showcases the successful application of advanced fermentation processes to produce ectoine at an industrial scale.

Rebecca's fermentation technology:

1. Optimized production strain: Rebecca may have developed or selected a highly efficient microorganism for ectoine biosynthesis, possibly through extensive screening or genetic engineering techniques.

2. Advanced fermentation process: The company's technology likely includes carefully optimized fermentation conditions, including specialized growth media, controlled osmotic stress induction, and efficient feeding strategies.

3. Innovative downstream processing: Rebecca may employ proprietary purification methods to achieve the high purity (99%) mentioned in their product description.

4. Quality control: As a factory directly supplying ectoin powder, Rebecca likely has stringent quality control measures in place to ensure consistent product quality and purity.

The high purity (99%) of Rebecca ectoin is a significant selling point, as it indicates a product suitable for a wide range of applications, including cosmetics, pharmaceuticals, and biotechnology. High-purity products is particularly valuable in these industries due to its stability, compatibility with biological systems, and potential for various formulations.

Rebecca's direct factory supply model suggests a streamlined production and distribution process, which may offer advantages in terms of cost-effectiveness and supply chain efficiency. This approach allows the company to maintain close control over product quality and respond quickly to market demands.

For potential customers and researchers interested in high-quality ectoin powder, Rebecca provides a point of contact (information@sxrebecca.com) for further inquiries. This direct line of communication can be valuable for those seeking detailed information about the product, its specifications, or potential collaborations in ectoine-related research and development.

References

1. Czech, L., Hermann, L., Stöveken, N., Richter, A. A., Höppner, A., Smits, S. H., ... & Bremer, E. (2018). Role of the extremolytes ectoine and hydroxyectoine as stress protectants and nutrients: genetics, phylogenomics, biochemistry, and structural analysis. Genes, 9(4), 177.

2. Kunte, H. J., Lentzen, G., & Galinski, E. A. (2014). Industrial production of the cell protectant ectoine: protection mechanisms, processes, and products. Current Biotechnology, 3(1), 10-25.

3. Pastor, J. M., Salvador, M., Argandoña, M., Bernal, V., Reina-Bueno, M., Csonka, L. N., ... & Vargas, C. (2010). Ectoines in cell stress protection: uses and biotechnological production. Biotechnology Advances, 28(6), 782-801.

4. Schwibbert, K., Marin‐Sanguino, A., Bagyan, I., Heidrich, G., Lentzen, G., Seitz, H., ... & Grammel, H. (2011). A blueprint of ectoine metabolism from the genome of the industrial producer Halomonas elongata DSM 2581T. Environmental Microbiology, 13(8), 1973-1994.

5. Widderich, N., Czech, L., Elling, F. J., Könneke, M., Stöveken, N., Pittelkow, M., ... & Bremer, E. (2016). Strangers in the archaeal world: osmostress-responsive biosynthesis of ectoine and hydroxyectoine by the marine thaumarchaeon Nitrosopumilus maritimus. Environmental Microbiology, 18(4), 1227-1248.